Solar Panel Recycling and End-of-Life Management – 2026 Guide

A practical, compliance-aware playbook for investment recovery (IR), facilities, procurement, sustainability, and decommissioning teams.

TL;DR

- Start with the hierarchy: prioritize reuse/refurbishment, then recycling, with disposal as the last resort.

- Plan for “early losses”: repowering, storms, shipping damage, and warranty returns can generate volume well before a project’s planned retirement.

- Separate the PV system into streams: modules, inverters/electronics, racking/metals, copper wiring, transformers/switchgear, and batteries each need different handling and channels.

- Buy outcomes, not promises: require chain-of-custody, downstream transparency, and certificates as contractual deliverables.

- Use an IR playbook: inventory → condition tiers → bid → qualify vendors → document → report.

1) Why PV end-of-life matters in 2026

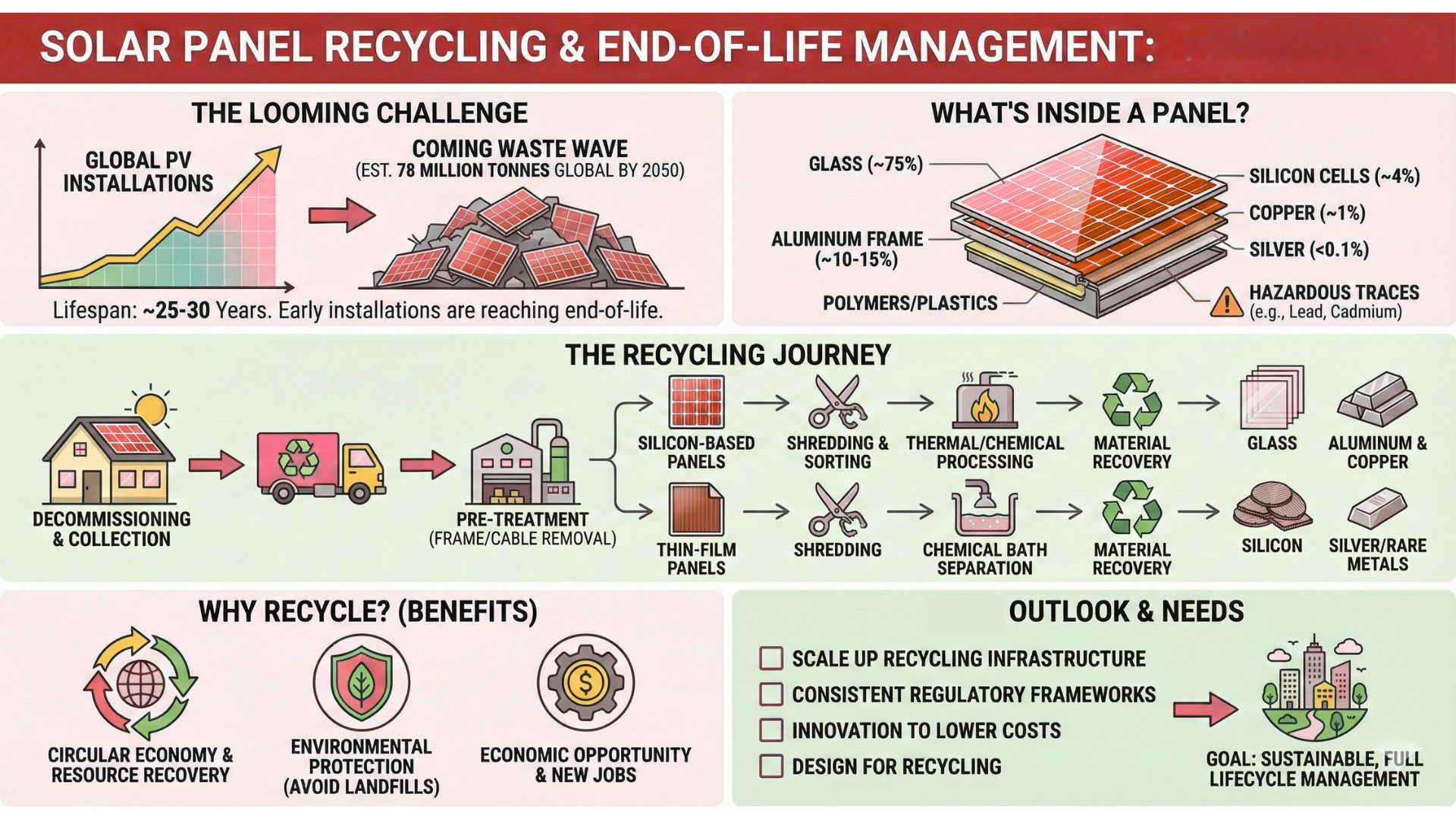

Solar deployment has scaled fast enough that end-of-life (EOL) is no longer a “future” problem.

Even when projects are designed for multi-decade operation, real-world conditions create early retirement events:

repowering, extreme weather, shipping/handling damage, fire exposure, and warranty-driven replacements.

In 2025, leading programs treat PV EOL as an asset disposition initiative—not a disposal task:

they plan lots, preserve resale eligibility where possible, competitively bid qualified vendors, and make documentation non-negotiable.

DOE’s overview of PV end-of-life management is a solid baseline if you’re aligning internal stakeholders:

DOE: End-of-Life Management for Solar Photovoltaics.

2) What “end-of-life” means for solar

“End-of-life” isn’t one moment. It’s a set of decision points that can occur for different reasons:

- Planned retirement: the project reaches the end of its contracted or economic performance period.

- Repowering: replacing modules/inverters earlier to improve output, standardize parts, or reduce O&M risk.

- Early losses: hail/wind damage, installation defects, breakage in transit, or localized performance failures.

- Partial replacements: specific strings/arrays swapped—creating mixed lots with variable resale potential.

IR takeaway: the sooner you control inventory and lot integrity, the more likely you can route assets into reuse/resale channels

instead of defaulting to “scrap pricing.”

3) Break the PV system into recoverable streams

PV sites are multi-material systems. Treat each category as its own disposition stream with its own vendors, pricing logic, and documentation:

- PV modules: crystalline silicon or thin-film; intact vs cracked; framed vs frameless.

- Inverters & electronics: power electronics, monitoring hardware, controls boards (often managed like e-scrap/ITAD-adjacent streams).

- Racking / structural steel / aluminum: high-volume metals recovery; typically commodity-driven.

- Copper wiring & combiner boxes: strong commodity value; requires theft controls and accurate weights.

- Transformers / switchgear / batteries (if present): higher compliance intensity; may require specialized contractors.

If you want an IR framework that translates well to PV, this guide is a useful internal reference:

Asset Disposition Explained (InvRecovery).

4) Reuse, refurbish, redeploy (highest value)

Before recycling, assess reuse safely and responsibly. Reuse can preserve substantially more value and often reduces environmental impact compared to materials-only recovery.

Typical reuse pathways:

- Internal redeployment: spares for O&M, non-critical applications, small expansions.

- Resale to secondary markets: buyers seeking lower-cost modules for off-grid or small commercial deployments.

- Donation (select cases): only when testing, liability, and documentation are addressed.

Minimum reuse screening (program-friendly)

- Preserve lot integrity: keep like-with-like (manufacturer/model), avoid mixing when possible.

- Visual inspection: cracked glass, backsheet damage, delamination, hotspots/burn marks, frame issues, junction box damage.

- Basic electrical checks: insulation resistance and/or IV curve testing where feasible (in-house or vendor-performed with documented results).

- Traceability: retain label/serial info when available; track quantities and condition grades.

- Clear resale terms: “as-is/where-is” language, tested/untested disclosure, and downstream responsibility clarity.

If reuse is not viable (or testing costs exceed recovery), move to recycling with clear acceptance standards and auditable reporting.

5) Recycling pathways & realistic recoverables

“Solar panel recycling” is not one process. Outcomes vary by module type, condition, and recycler technology.

Many programs start by recovering high-mass, easier-to-separate materials (frames, glass, junction boxes),

then progress toward higher-purity recovery as scale and economics support it.

Common recycling approaches (high-level)

- Mechanical separation: dismantling, crushing, and sorting to recover bulk materials.

- Thermal processing: heat-assisted separation of laminated layers (varies by method and module type).

- Chemical processing: used in some advanced systems to target higher-purity recovery of select materials.

What to “buy” in an IR-friendly recycling contract

| Outcome level | What it usually includes | Best for | Controls to require |

|---|---|---|---|

| Materials recovery (baseline) | Frames/glass + segregated metals where feasible | High-volume, mixed-condition lots | Weight tickets, chain-of-custody, downstream summary |

| Enhanced recovery | Additional processing for higher-value constituents (capability varies) | Homogeneous lots, recycler with validated capability | Process description, audit rights, yield reporting |

| ESG-optimized diversion | Defined diversion targets and detailed reporting boundaries | Organizations with strict disclosure requirements | Clear diversion definitions, verification, reporting cadence |

For global context and EOL framing, IRENA/IEA-PVPS remains one of the most-cited sources:

IRENA/IEA-PVPS: End-of-Life Management of Solar PV Panels.

6) Compliance landscape (U.S. focus + EU snapshot)

United States (EPA / RCRA baseline)

In the U.S., when a solar panel is discarded, it is regulated as solid waste under RCRA, and it may be regulated as hazardous waste

depending on how it is characterized (for example, via testing/knowledge of toxicity characteristics).

EPA’s pages below are the best starting point for program teams aligning legal/EHS with operations:

- EPA: End-of-Life Solar Panels – Regulations and Management

- EPA: Universal Waste Regulations for Solar Panels (rulemaking initiative)

European Union (WEEE snapshot)

For organizations with EU exposure, PV panels fall under the WEEE framework (extended producer responsibility).

Official text:

Directive 2012/19/EU (WEEE).

Compliance note: This guide is educational and not legal advice. Always verify jurisdiction- and project-specific requirements with qualified counsel and EHS professionals.

7) A repeatable end-of-life program (IR playbook)

Step 1: Build a bid-ready inventory

- Module manufacturer/model and approximate age

- Condition tiers: intact, minor damage, broken glass, unknown

- Estimated counts and weights (by lot/site)

- Site logistics: staging area, loading method, access restrictions

- Associated equipment counts: inverters, racking, cable, transformers, batteries

- Required outcomes: reuse vs recycle targets, documentation requirements

Step 2: Route assets using a simple decision tree

- Reuse viable? If condition/testing supports it, pursue redeploy/resale with clear terms.

- Recycling viable? If reuse fails or is uneconomic, choose recyclers by capability + transparency + reporting.

- Disposal only when necessary, and only with documented compliance support.

Step 3: Run a structured bid

Force apples-to-apples comparisons in the RFP:

- Pricing by condition tier

- Transportation assumptions and packaging requirements

- Downstream transparency and diversion reporting boundaries

- Turnaround time and certificate delivery SLAs

- Insurance, indemnities, and site safety requirements

If you want to align PV EOL with broader IR methods, these internal resources map well:

Asset Recovery Services (InvRecovery) and

Circular Economy Asset Management (2025 Implementation Guide).

8) Vendor qualification checklist

- Capability fit: crystalline vs thin-film, intact vs broken acceptance, handling controls

- Downstream transparency: where materials go, how processed, and what is landfilled (if any)

- Documentation bundle: chain-of-custody, weight tickets, bills of lading, certificates

- Audit rights: desk audits and (when justified) site audits

- Safety & logistics: packaging specs, breakage handling, site procedures, trained labor

- Data handling (when relevant): for inverters/controls that may contain logs or configuration data

Need help shortlisting partners? Start here:

IRA Member Service Directory – Download.

9) Contract clauses that prevent surprises

- Defined outcomes: reuse/recycle/disposal definitions and allowable thresholds

- Documentation as deliverables: certificates and reporting required for invoice approval

- Downstream controls: no unapproved downstream changes; transparency requirements

- Breakage responsibility: packaging standards and liability allocation

- Audit rights: verify claims and downstream vendors

- Compliance responsibilities: who characterizes waste, who signs manifests (if applicable), and record retention requirements

10) KPIs & ESG reporting

Choose KPIs that are auditable and decision-useful:

- Reuse rate: % redeployed/resold (by count and by weight)

- Diversion rate: % recycled vs disposed (by weight, with defined boundaries)

- Net recovery value: proceeds minus logistics and processing costs

- Documentation completeness: % lots with full chain-of-custody and certificates

- Cycle time: days from decommission to completed documentation

For teams that already manage electronics, the documentation rigor in ITAD is a useful model:

ITAD – Complete Guide 2025.

11) How InvRecovery / IRA members typically approach PV EOL

High-performing IR teams treat PV EOL as a blend of asset recovery, environmental compliance, and vendor governance.

The IRA ecosystem supports this by helping teams find vetted service partners and apply repeatable IR methods across asset classes.

- Find categories of vendors via the Member Service Directory.

- Use IR best practices to structure bids and validate outcomes (see IR Articles & Best Practices).

- If you need guidance building an internal SOP/RFP, use Contact InvRecovery.

FAQs

Are solar panels hazardous waste?

In the U.S., discarded panels are regulated as solid waste under RCRA and may be regulated as hazardous waste depending on how they’re characterized

(testing and/or knowledge of materials and toxicity characteristics). Start with EPA’s guidance and confirm state-specific overlays.

Can solar panels be recycled?

Yes. Recycling exists, but processes and outcomes vary by module type, condition, and recycler capability.

Best practice is to contract for defined outcomes and documentation (weights, downstream transparency, and certificates).

What’s the best first step for an IR team?

Build a bid-ready inventory with condition tiers and site logistics, then run a structured bid with documentation requirements as deliverables.

Should we prioritize reuse over recycling?

Generally yes—reuse can preserve more value and reduce lifecycle impacts, but only when testing, safety, traceability, and liability are managed.

What documentation should we require?

At minimum: chain-of-custody, bills of lading, weight tickets, downstream summary, and certificates (recycling/reuse/disposal as applicable).

Trusted references

- U.S. Department of Energy – End-of-Life Management for Solar Photovoltaics

- DOE FEMP – Prepare for the End of a Performance Period (PV)

- U.S. EPA – End-of-Life Solar Panels: Regulations and Management

- U.S. EPA – Universal Waste Regulations for Solar Panels (initiative)

- IRENA / IEA-PVPS – End-of-Life Management: Solar Photovoltaic Panels

- EUR-Lex – Directive 2012/19/EU (WEEE)

- InvRecovery – IRA Member Service Directory (Download)

- InvRecovery – Asset Disposition Explained

- InvRecovery – Asset Recovery Services Guide

- InvRecovery – Circular Economy Asset Management (2025)