Preventing Inventory Buildup: Strategies for Lean Stock Management

Having excess stock can create a huge headache for a company. It restricts cash flow, consumes high amounts of inventory space, and raises the risk of products becoming outdated. If products are not moving off the shelves as rapidly as they should, companies may have to engage in price markdowns which lowers profit margins.

That’s where lean stock management comes in. By providing and maintaining the optimal level of supply as per market demand, companies can eliminate inefficiencies, reduce the waste generated, and most importantly, increase available capital for business expansion. Whether a small-scale retailer or even a complete distribution center, smart inventory management strategies may be adopted to maintain market competitiveness and profitability.

In this blog, we’ll explore key techniques for preventing inventory buildup, from accurate demand forecasting to real-time inventory tracking. By the end, you’ll have actionable insights to keep your stock levels lean, optimized, and cost-effective.

Understanding Inventory Buildup

When a company holds excess inventory or excess stock, the result is an overflow of wasted capital. This can occur due to inaccurate demand forecasts, over-ordering, slow sales, or supply chain delays and requires a reevaluation of warehouse strategy. When products remain unsold for too long, they consume critical resources and cash flow that hamper investments.

Excessive stock can also create operational challenges, such as increased storage costs, higher risk of product damage or expiration, and inefficient warehouse management. Additionally, businesses may be forced to sell items at a discount, reducing profit margins. By understanding the causes and effects of inventory accumulation, companies can take proactive steps to avoid unnecessary stock buildup and maintain a lean, efficient inventory system.

The Principles of Lean Stock Management

Lean stock management is defined as maintaining just the right amount of inventory to meet demand without incurring excess waste, storage costs, or over-stocking items. The primary concern when implementing lean stock management is to reduce excess stock, improve operational efficiency, and ensure a steady supply chain. With this maintenance practice, businesses can avoid overstocking inventory which is often unsold and financially drains the business, and understocking items which is a surefire way to miss sales opportunities.

Accurate demand forecasting is a critically important component of lean inventory management practices. Using a combination of past sales records along with trends in the market, businesses can foresee customer requirements and vary stock quantities to those needs. Also important is the control of stock which encompasses routine inventory counts and setting reorder levels at optimum levels to curb stockpiling.

With the implementation of lean stock management approaches, businesses can operate by cutting down expenditures while ensuring there is optimum stock of every item without losing efficiency.

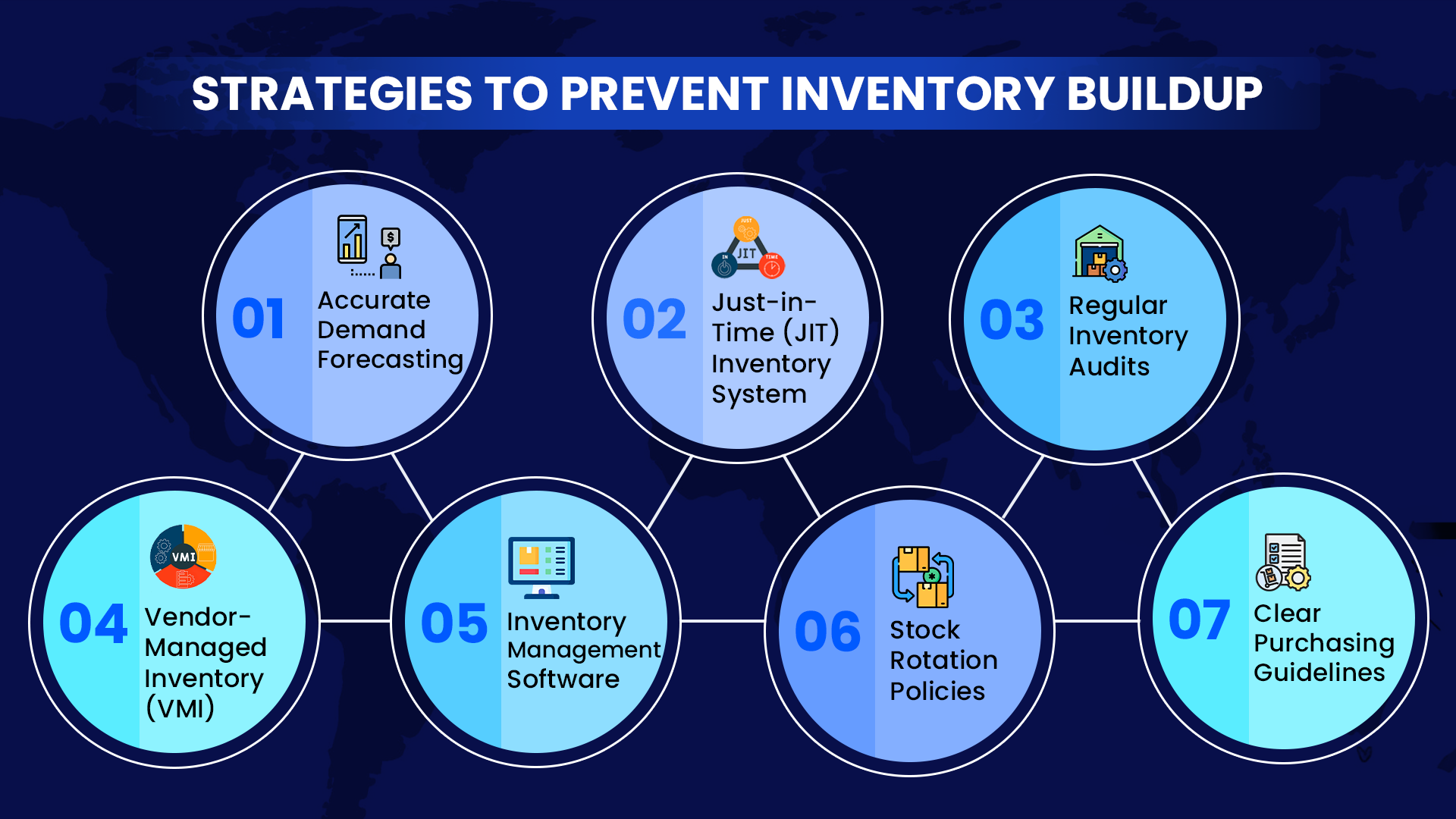

Strategies to Prevent Inventory Buildup

For a business to run seamlessly, keep business operations efficient, and remain cost-effective is essential. Excess inventory can restrict a company’s cash flow and increase the associated storage expenses, and there is also a risk that the goods may become obsolete. Strategic smart inventory management not only avoids wastage but also helps businesses maintain ideal stock levels. Here are some effective ways to prevent stock accumulation:

Accurate Demand Forecasting: These tools can model future sales by incorporating past sales, seasonality, and other market factors. Updating business forecasts regularly ensures a business plans its orders such that it does not cross over the brink leading to unnecessary overstocking or running out of products.

JIT Inventory System: Just-in-time (JIT) is a business system that enables an organization to place orders for new stock only when they are needed, as opposed to storing large quantities of stock. This approach lowers storage costs and facilitates waste reduction. However, to meet these requirements, strong supplier relationships are necessary for timely deliveries.

Regular Inventory Audits: Doing routine inventory audits allows companies to monitor the amount of stock on hand, locate items that are not selling, and remove outdated products. These checks also enhance accuracy, thereby minimizing the chances of overstocking or understocking.

Vendor-Managed Inventory (VMI): When using Vendor-Managed Inventory (VMI), suppliers observe the inventory levels and restock as required. This method enhances efficiency and minimizes the administrative burden while ensuring that organizations are sufficiently stocked without going overboard.

Inventory Management Software: With inventory management software, businesses can automate stock tracking, which reduces errors as well as manual work. Inventory management software provides up-to-date stock level insights, alerting businesses when inventory levels are optimal, helping them make better decisions, and preventing overstocking.

Stock Rotation Policies (FIFO Method): The First-In, First-Out (FIFO) method guarantees that previous stocks are used or sold before the new stocks. This is crucial for perishables because it minimizes product damage and lowers waste due to outdated products.

Clear Purchasing Guidelines: By defining specific purchasing policies, bulk ordering will be controlled and stock replenishment will adhere to a set strategy. Defining approval levels for large purchases will also ensure stock is kept at a balanced level without excess accumulation.

Benefits of Lean Stock Management

Lean stock management is vital in ensuring that a business runs efficiently while minimizing operational costs. Having an optimized stock level aids a business to avoid overspending on buying goods which helps minimize storage costs and overall financial wastage. It also improves a business’s cash flow as unnecessarily high capital expenditure on stock is avoided allowing for investment in other areas of growth.

Controlling stock improves a business’s operational efficiency due to the enhanced organization of storage spaces and faster order processing. Improvement in these areas results in increased productivity and customer satisfaction. Additionally, the prevention of overproduction combined with the prevention of excess inventory allows reduction of wastage making lean stock management more environmentally friendly.

Common Challenges and How to Overcome Them

Integrating lean stock control brings its unique problems, but working to overcome them is central to operating a lean and profitable company. One key problem is changing resistance to practices already established. Employees and managers could be set in their ways and reluctant to switch to a newer version for no good reason. To remedy this, businesses need to teach their workers proper stock manipulation strategies and how to take advantage of streamlined processes.

Another hurdle is the lack of innovation. Many small enterprises do not have the resources to implement inventory control systems or do not have the technical know-how. The answer lies in starting with affordable digital tools to get the company’s foot in the door and scaling out as demand dictates.

Managing supplier relationships tends to be the most difficult challenge when dealing with external vendors for stock control logistics. Appropriate partner approaches, communication, and negotiation of reasonable terms will allow for adequate overstock or shortage control for the smooth operation of the supply chain.

Conclusion

Efficient lean stock management governs inventory build-up and ensures that all your business operations run smoothly. Making accurate demand forecasting, JIT inventory, regular audits, and other strategies aids in waste reduction, cost minimization, and opening up much-needed storage. Maintaining very good relationships with suppliers, in conjunction with inventory management software, increases productivity even more. Although there are some challenges such as reluctance to implement change, adopting new technology, or any other flexibility issues, being proactive makes it easier to stay ahead. For long-term success, adopting smart business practices builds a profitable stock management system. An effective inventory system also increases a business’s profitability along with customer service satisfaction, since clients get the products they want when they need them.